BASICS OF TRACK-ETCHING TECHNOLOGY

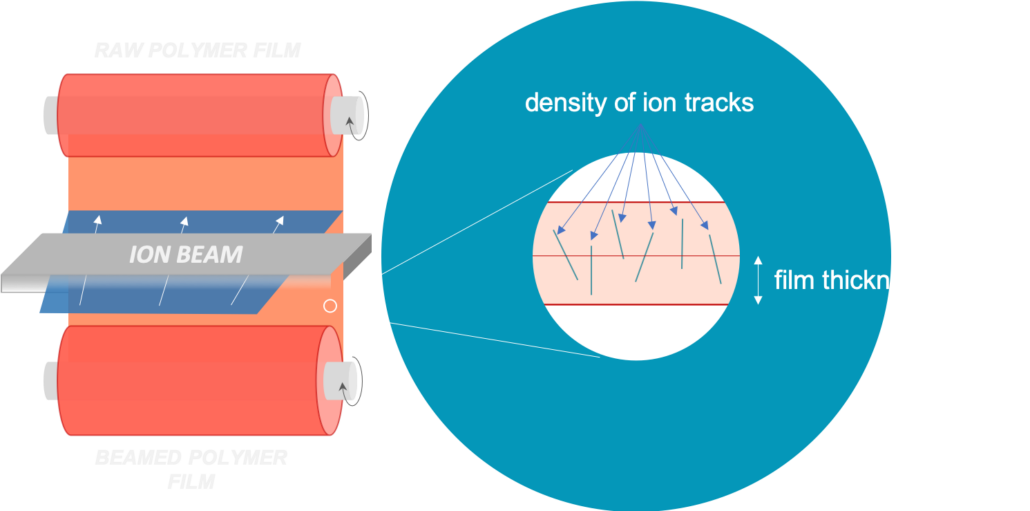

Beaming of raw polymer films

Heavy ions are generated by a ion source and then accelerate by a cyclotron to energy as high as 4 MeV/uma.

For the beaming, the polymer film is unwounded at a constant speed under vacuum through the scanned ion beam ; the tracks density (or desired pore density) is therefore precisely defined by the ion beam intensity and the film velocity.

The film is pulled over a bending roll to increase the angular spread of the tracks, and thus raise the selectivity of the membrane filters by avoiding parallel double tracks.

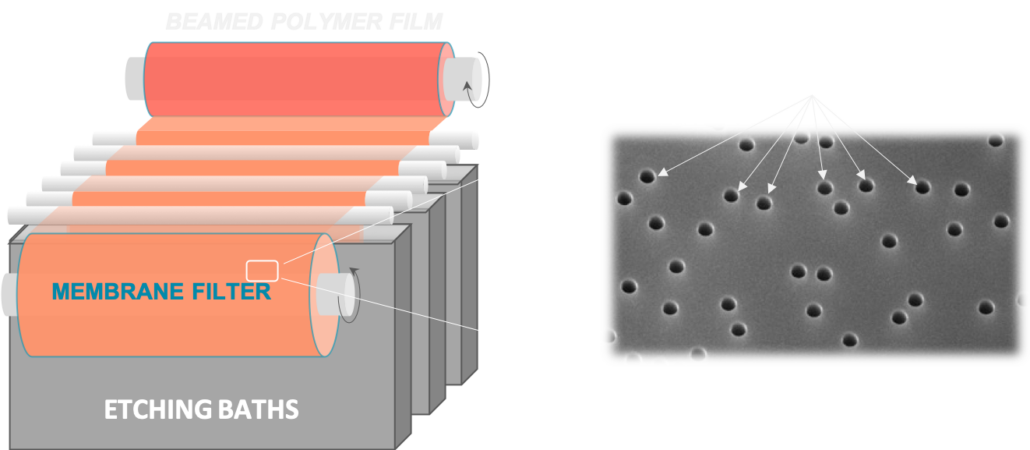

Chemical etching of beamed polymer films

Linear tracks created during the beaming are mainly characterised by macromolecular chain scissions, highly hydrophilic chemical groups and free vacuum.

Tracks are therefore more sensitive to chemicals than surrounding bulk polymer, and can be selectively etched leading to their revelation into pores.

Chemical etching is commonly carried out with an aqueous alkaline solution at a well-controlled concentration and temperature. It is mainly characterised by the track etching rate (Vt) and the bulk etching rate (Vg). A high ratio Vt/Vg is needed to obtain an homogeneous membrane filter with cylindrical pores.

Pore size is defined by the etching conditions while pore density is defined by the beaming parameters. Pore size and pore density can be therefore independently selected.

State of the art

State-of-the-art track-etching technology can be applied to polyimide (it4ip exclusivity), polyester and polycarbonate. Learn more about the specific features of our membranes.